The Very Best Commercial Refrigeration Repair Business in Toronto Revealed

The Very Best Commercial Refrigeration Repair Business in Toronto Revealed

Blog Article

Taking Full Advantage Of Effectiveness: Commercial Refrigeration Repair Techniques for Cost-Effective Solutions

Assessing Refrigeration System Performance

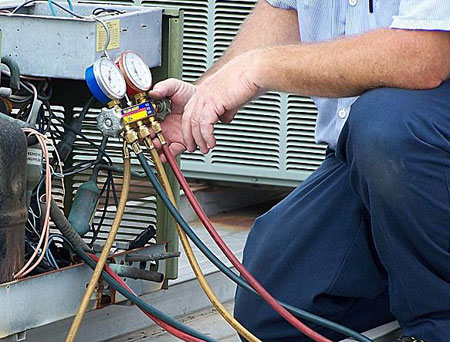

To properly assess the performance of an industrial refrigeration system, it is necessary to perform detailed analyses of its essential parts and functional criteria. The very first step in evaluating system efficiency is analyzing the functionality of the compressor.

Additionally, examining the condenser and evaporator coils is extremely important. Clogged up or dirty coils can significantly influence the system's efficiency by impeding warm transfer procedures. Cleaning up the coils consistently and making certain correct air flow around them can maximize the system's air conditioning capacity and decrease energy consumption. Keeping an eye on cooling agent degrees and stress is also essential in assessing system performance. Reduced refrigerant levels or abnormal stress can indicate leaks or malfunctioning parts that require instant attention to stop system failures and pricey repair services. By systematically evaluating these essential elements and functional specifications, companies can guarantee their industrial refrigeration systems run at peak efficiency degrees, reducing downtime and making the most of power efficiency.

Carrying Out Preventative Upkeep Actions

Evaluating the efficiency of a business refrigeration system supplies valuable insights that can notify the implementation of preventative upkeep procedures essential for sustaining optimal capability and long life. By developing a normal upkeep timetable, refrigeration systems can operate effectively, reducing power consumption and decreasing the threat of unanticipated failures. Ultimately, investing in preventative maintenance measures is a cost-effective approach that aids services prevent expensive repairs and downtime, making certain continual and dependable refrigeration system efficiency.

Identifying Common Refrigeration Issues

One of the key elements in preserving commercial refrigeration systems is immediately determining usual problems that may occur during their procedure. One widespread problem is poor cooling, commonly brought on by filthy condenser coils or a malfunctioning compressor. Regular cleansing of the condenser coils and guaranteeing correct ventilation around the unit can aid avoid this problem. Another usual issue is refrigerant leaks, which can result in inefficient cooling and potential environmental threats. Monitoring refrigerant degrees and conducting normal evaluations for leakages can assist reduce this problem. Furthermore, faulty gaskets on doors, causing air leaks, can create the refrigeration system to work more challenging to maintain the desired temperature. Routine inspection and substitute of harmed gaskets are important to avoid power waste. Last but not least, unusual sounds such as knocking, clanking, or hissing can suggest underlying mechanical concerns that need prompt interest to avoid additional damages. By without delay identifying and resolving these typical refrigeration issues, companies can guarantee the reliable operation of their systems and reduce costly repair services.

Utilizing Energy-Efficient Fixing Techniques

When thinking about commercial refrigeration fixing, carrying out energy-efficient methods is extremely important to enhancing the system's efficiency and minimizing functional expenses. One of the essential methods in accomplishing power efficiency is guaranteeing my link that the refrigeration system is properly maintained. Normal maintenance, such as cleaning condenser coils, looking for cooling agent leakages, and adjusting temperature setups, can significantly improve power efficiency.

Another energy-efficient repair strategy is updating to high-efficiency elements - commercial refrigeration repair. By replacing older, less efficient get rid of energy-efficient choices, such as ECM fan electric motors or LED illumination, organizations can lower energy usage and lower energy prices. In addition, mounting programmable thermostats and energy management systems can aid control temperatures a lot more efficiently, preventing unnecessary energy use

Furthermore, enhancing the system's insulation and securing any type of leaks can additionally add to power financial savings. Proper insulation helps preserve constant temperatures within the refrigeration device, decreasing the workload on the system and boosting general performance. By integrating these energy-efficient repair service methods, services can not just decrease their environmental influence yet additionally achieve long-lasting expense savings.

Optimizing Refrigeration System Lifespan

To make sure the durability and ideal performance of business refrigeration systems, keeping energy-efficient repair practices is essential, with an emphasis now shifting towards making the most of the refrigeration system lifespan. Enhancing the life-span of a refrigeration system entails positive upkeep, prompt fixings, and adherence to producer guidelines.

Additionally, investing in top quality parts and parts during fixings and substitutes can improve the durability of the refrigeration system. By focusing on positive upkeep and utilizing quality parts, businesses can optimize the lifespan of their commercial refrigeration try this out systems, inevitably minimizing downtime and functional prices.

Final Thought

To conclude, by routinely analyzing refrigeration system efficiency, executing preventative maintenance actions, determining common refrigeration issues, utilizing energy-efficient fixing strategies, and maximizing the system's life expectancy, businesses can make the most of efficiency and minimize costs connected with commercial refrigeration repair work. These affordable options aid to make sure that refrigeration systems operate at peak performance, eventually bring about boosted productivity and profitability for services over time.

When taking into consideration industrial refrigeration repair work, executing energy-efficient methods is critical to maximizing the system's performance and minimizing functional costs.To make sure the durability and optimal efficiency of commercial refrigeration systems, keeping energy-efficient repair techniques is necessary, with a focus currently moving towards maximizing the refrigeration system life expectancy. Maximizing the life expectancy of a refrigeration system involves aggressive maintenance, timely repairs, and adherence to supplier standards.

Report this page